Dennis is making a new round of urns to restock the inventory. In addition to the urn on the lathe, there are other groups of roughed-out vessels all over the shop–on the floor, in baskets, and upside down on the drying rack.

Dennis is making a new round of urns to restock the inventory. In addition to the urn on the lathe, there are other groups of roughed-out vessels all over the shop–on the floor, in baskets, and upside down on the drying rack.

The photo shows the arm brace and the 1″ diameter boring bar that is needed to hollow a vessel as large as a burial urn. This one is still very wet wood.

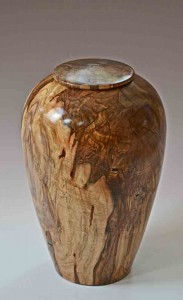

After the initial hollowing, and several months of drying out, Dennis will remount the vessel and turn the walls to the final, even wall thickness of about 1/4″. He adds threaded inserts and turns a lid from the same wood.

The final stage is sanding and finishing the urn, often with the multi-step patination.

Of course, for the best selection, it is wise to buy a burial urn in advance of the need for it.